23/12/10

15/12/10

Hello world!

Welcome to WordPress.com. This is your first post. Edit or delete it and start blogging!

19/09/10

Backhoe Loaders

Backhoes - a better way to dig.

Designed and built with direct input from backhoe customers around the world, the Volvo backhoe loader is everything you’ve ever wanted in a machine – a loader with the strength and simplicity of a Volvo wheel loader, a backhoe with the power and performance of a Volvo excavator, an operator’s station that will envelop you in comfort and serviceability features that will ensure a long and productive machine life.

It’s all here: customer-driven design, power and reliability. And with dig depths, breakout forces and operating capacities rated higher than virtually every competitive model in its price class, the Volvo backhoe loader rises to your challenges – every day.

It’s a better way, and it’s all Volvo.

Designed and built with direct input from backhoe customers around the world, the Volvo backhoe loader is everything you’ve ever wanted in a machine – a loader with the strength and simplicity of a Volvo wheel loader, a backhoe with the power and performance of a Volvo excavator, an operator’s station that will envelop you in comfort and serviceability features that will ensure a long and productive machine life.

It’s all here: customer-driven design, power and reliability. And with dig depths, breakout forces and operating capacities rated higher than virtually every competitive model in its price class, the Volvo backhoe loader rises to your challenges – every day.

It’s a better way, and it’s all Volvo.

Any person Spotlight

“I like the breakout power on the Volvo backhoes. I like the all-around strength of the hydraulics. The hydraulics are responsive and they’re fast. Like when you’re loading something, you can start lifting and moving forward at the same time – when you get there the bucket will be up there, not to worry!"

"And I like the push-button to control forward and backward motion. That control is all on the joystick for the front loader boom. You don’t have to take your hand off the stick.”

10/09/10

Barnhart Makes Special Appearance in 2011 Super Bowl Commercial

Most of us are aware of the product placement advertising that sneaks its way into popular television shows and movies. In fact, the clever folks at Bud Light poked fun at the marketing methods during this year's Super Bowl commercial lineup:

But does product placement work in commercials themselves? I don't think many marketing teams have attempted it.

However, Chrysler's 2011 Super Bowl commercial "Imported from Detroit," featuring Rap Artist Eminem, inadvertently promoted Barnhart Crane & Rigging Company with a quick product placement shot.

That's right. Those are official Barnhart cranes. You can't see the Barnhart name, but they made the commercial.

That's right. Those are official Barnhart cranes. You can't see the Barnhart name, but they made the commercial.

Here's the full commercial below. The crane shot appears in the first ten seconds of the video.

So, how does Barnhart stand to benefit from this subliminal product placement? We can only hope that anytime someone sees a Chrysler vehicle or listens to an Eminem song, this image will flash in their minds:

But does product placement work in commercials themselves? I don't think many marketing teams have attempted it.

However, Chrysler's 2011 Super Bowl commercial "Imported from Detroit," featuring Rap Artist Eminem, inadvertently promoted Barnhart Crane & Rigging Company with a quick product placement shot.

That's right. Those are official Barnhart cranes. You can't see the Barnhart name, but they made the commercial.

That's right. Those are official Barnhart cranes. You can't see the Barnhart name, but they made the commercial.Here's the full commercial below. The crane shot appears in the first ten seconds of the video.

So, how does Barnhart stand to benefit from this subliminal product placement? We can only hope that anytime someone sees a Chrysler vehicle or listens to an Eminem song, this image will flash in their minds:

02/09/10

HEAVY EQUIPMENT INDUSTRY RESOURCES

FORKLIFT fact

The forklift is a powered truck fitted with steel forks on its front end, used to lift and transport material. The two parallel steel forks slide beneath the material, often loaded onto a wooden pallet or skid, and then hoisted. Most are fitted with small wheels and are really only practical on finished or paved surfaces. Some forklifts carry their cargo on one side of the vehicle; these are called sideloaders. Though small by comparison to most heavy equipment vehicles, it has become indispensible for the warehousing and manufacturing sectors. Major manufacturers of forklifts (by market share) include Toyota, KION Group, Jungheinrich, NAACO Industries, Inc. (which includes Yale and Hyster brands), Komatsu, Manitou, Mitsubishi, Nissan, Caterpillar, Clark, and Crown Equipment, though many more brands are available among used forklifts. (Over the years, many other brands such as Allis-Chalmers have either gone out of business or been assumed into larger companies through acquisitions.)

The forklift is a powered truck fitted with steel forks on its front end, used to lift and transport material. The two parallel steel forks slide beneath the material, often loaded onto a wooden pallet or skid, and then hoisted. Most are fitted with small wheels and are really only practical on finished or paved surfaces. Some forklifts carry their cargo on one side of the vehicle; these are called sideloaders. Though small by comparison to most heavy equipment vehicles, it has become indispensible for the warehousing and manufacturing sectors. Major manufacturers of forklifts (by market share) include Toyota, KION Group, Jungheinrich, NAACO Industries, Inc. (which includes Yale and Hyster brands), Komatsu, Manitou, Mitsubishi, Nissan, Caterpillar, Clark, and Crown Equipment, though many more brands are available among used forklifts. (Over the years, many other brands such as Allis-Chalmers have either gone out of business or been assumed into larger companies through acquisitions.)Forklift operators must be well trained to operate the machine safely and effectively. Because most models steer from the rear, manouevering quickly can take some getting used to. Additionally, moving with a load held high upon the forks can upset the forklift's low center of gravity, and risk tipping. To keep the forklift balanced, some machines have a counterweight at the back, though in most cases it is the actual engine or battery that acts as the rear weight. Most forklifts have an overhead guard above the cab to protect the operator from falling debris. The exception would be those motorized pallet jacks upon which the operator stands.

Become A Certified Crane Operator

In order to become a certified crane operator crane operator you must meet several requirements.

1. You must be at least 18 years old

2. You must pass a drug test and an ASME ANSI B30.5 physical examination, D.O.T. and D.M.V medicals are also accepted

3. You must pass a written and practical exam administered by an accredited entity on the specific type crane you will operate.

For telescopic boom mobile cranes the term “specific type crane” is separated into 2 categories small telescopic boom cranes and large telescopic boom cranes. Tonnage use to be the distinguishing factor between the cranes. However they are now distinguished differently the small telescopic boom crane is referred to as" fixed cab" and the large telescopic boom crane is referred to as the "swing cab." The cranes Tonnage is no longer the distinguishing factor.

As far as the written exams you will be taking 3 separate exams.

The first written exam is the core. This exam consists of a 90 question which is all multiple choice and you are given 90 minutes to complete it.

You will also be given 2, 26 question specialty exams, one on the large telescopic boom crane and one on the small telescopic boom crane these exams are also multiple choice within these exams there will be several load chart questions which you will have to calculate Net Capacities, Gross capacities, as well as some specific questions pertaining to the load charts you are given 55 minutes to complete each of these exams.

Once you have met these criteria, you are now become a nationally certified crane operator.

Many organizations do not consider you to be a fully certified crane operator until you have a crane operator certification card in your pocket. Keep in mind even after you have passed all of your crane operator certification tests it takes International Assessment Institute (IAI) the national crane operator certification testing company 2-3 weeks to mail you the results of the written tests and about 3-4 weeks to mail you the results of the national crane operator certification practical (hands on) tests. As a result of this delay your crane certification card might not come in for about 1 month after you have completed all of your national crane operator certification tests.

If you become a certified crane operator the state of Washington has some minimum hour requirements for different types of cranes.

20/08/10

Telescopic Cranes

Telescopic Cranes are mobile cranes whose boom consists of several square

tubes fitted inside each other. As these cranes expand, a hydraulic mechanism

extends the tubes to increase their working height.

| ||

| Cranes |

|

| Telescopic Cranes |

06/08/10

All About Crane Machine

All About Crane Machine

The crane is a construction devise comprised of an arm, a winch, and a wire rope to create mechanical advantage and lift heavy objects. The arm may be hydraulically controlled and connected to a pivot point, or may consist of a vertical mast and a horizontal boom. Many different types of cranes exist, each tailored for a specific purpose, but they all work on the same general principles, particularly leverage.

The crane is a construction devise comprised of an arm, a winch, and a wire rope to create mechanical advantage and lift heavy objects. The arm may be hydraulically controlled and connected to a pivot point, or may consist of a vertical mast and a horizontal boom. Many different types of cranes exist, each tailored for a specific purpose, but they all work on the same general principles, particularly leverage.

Cranes may be thought of as the oldest of heavy-equipment machines, having been invented by the Ancient Greeks for the building of temples. Those cranes, right up until the Industrial Revolution, utilized human or animal power to turn the winch or move the crane, though sometimes they could be connected to a water or wind mill. The first mechanically powered cranes utilized steam engines in the late 18th or early 19th Centuries. Modern cranes are powered by either electric or internal combustion engines, and use hydraulics to create even more lifting power.

Cranes may be thought of as the oldest of heavy-equipment machines, having been invented by the Ancient Greeks for the building of temples. Those cranes, right up until the Industrial Revolution, utilized human or animal power to turn the winch or move the crane, though sometimes they could be connected to a water or wind mill. The first mechanically powered cranes utilized steam engines in the late 18th or early 19th Centuries. Modern cranes are powered by either electric or internal combustion engines, and use hydraulics to create even more lifting power.

There are many types of cranes. The one seen most obviously along the skyline is the tower crane, which has a fixed base and is constructed on site and dismantled once a project is complete. These cranes employ a counter balance on the short end of the boom, while the long end does the lifting. Because of their height and their slender base, they must be engineered to withstand forces that would cause them to tip, and are often braced by the very structure they are building. Truck mounted mobile cranes , known as boom trucks, generally employ a telescopic crane mechanism, allowing them to minimize their size for travel to and from job sites. Floating cranes are constructed upon pontoons, and are used mainly in the construction of bridges and ports, though they are sometimes also used to move awkward loads off of ships, and in salvage operations. Some floating cranes have lift capacities of 10,000 tonnes.

There are many types of cranes. The one seen most obviously along the skyline is the tower crane, which has a fixed base and is constructed on site and dismantled once a project is complete. These cranes employ a counter balance on the short end of the boom, while the long end does the lifting. Because of their height and their slender base, they must be engineered to withstand forces that would cause them to tip, and are often braced by the very structure they are building. Truck mounted mobile cranes , known as boom trucks, generally employ a telescopic crane mechanism, allowing them to minimize their size for travel to and from job sites. Floating cranes are constructed upon pontoons, and are used mainly in the construction of bridges and ports, though they are sometimes also used to move awkward loads off of ships, and in salvage operations. Some floating cranes have lift capacities of 10,000 tonnes.

The crane is a construction devise comprised of an arm, a winch, and a wire rope to create mechanical advantage and lift heavy objects. The arm may be hydraulically controlled and connected to a pivot point, or may consist of a vertical mast and a horizontal boom. Many different types of cranes exist, each tailored for a specific purpose, but they all work on the same general principles, particularly leverage.

The crane is a construction devise comprised of an arm, a winch, and a wire rope to create mechanical advantage and lift heavy objects. The arm may be hydraulically controlled and connected to a pivot point, or may consist of a vertical mast and a horizontal boom. Many different types of cranes exist, each tailored for a specific purpose, but they all work on the same general principles, particularly leverage.

Cranes may be thought of as the oldest of heavy-equipment machines, having been invented by the Ancient Greeks for the building of temples. Those cranes, right up until the Industrial Revolution, utilized human or animal power to turn the winch or move the crane, though sometimes they could be connected to a water or wind mill. The first mechanically powered cranes utilized steam engines in the late 18th or early 19th Centuries. Modern cranes are powered by either electric or internal combustion engines, and use hydraulics to create even more lifting power.

Cranes may be thought of as the oldest of heavy-equipment machines, having been invented by the Ancient Greeks for the building of temples. Those cranes, right up until the Industrial Revolution, utilized human or animal power to turn the winch or move the crane, though sometimes they could be connected to a water or wind mill. The first mechanically powered cranes utilized steam engines in the late 18th or early 19th Centuries. Modern cranes are powered by either electric or internal combustion engines, and use hydraulics to create even more lifting power.  There are many types of cranes. The one seen most obviously along the skyline is the tower crane, which has a fixed base and is constructed on site and dismantled once a project is complete. These cranes employ a counter balance on the short end of the boom, while the long end does the lifting. Because of their height and their slender base, they must be engineered to withstand forces that would cause them to tip, and are often braced by the very structure they are building. Truck mounted mobile cranes , known as boom trucks, generally employ a telescopic crane mechanism, allowing them to minimize their size for travel to and from job sites. Floating cranes are constructed upon pontoons, and are used mainly in the construction of bridges and ports, though they are sometimes also used to move awkward loads off of ships, and in salvage operations. Some floating cranes have lift capacities of 10,000 tonnes.

There are many types of cranes. The one seen most obviously along the skyline is the tower crane, which has a fixed base and is constructed on site and dismantled once a project is complete. These cranes employ a counter balance on the short end of the boom, while the long end does the lifting. Because of their height and their slender base, they must be engineered to withstand forces that would cause them to tip, and are often braced by the very structure they are building. Truck mounted mobile cranes , known as boom trucks, generally employ a telescopic crane mechanism, allowing them to minimize their size for travel to and from job sites. Floating cranes are constructed upon pontoons, and are used mainly in the construction of bridges and ports, though they are sometimes also used to move awkward loads off of ships, and in salvage operations. Some floating cranes have lift capacities of 10,000 tonnes. Large construction companies may have several cranes among their heavy equipment. For companies which are not regularly using cranes on their projects, many industrial equipment rental stores exist.

20/07/10

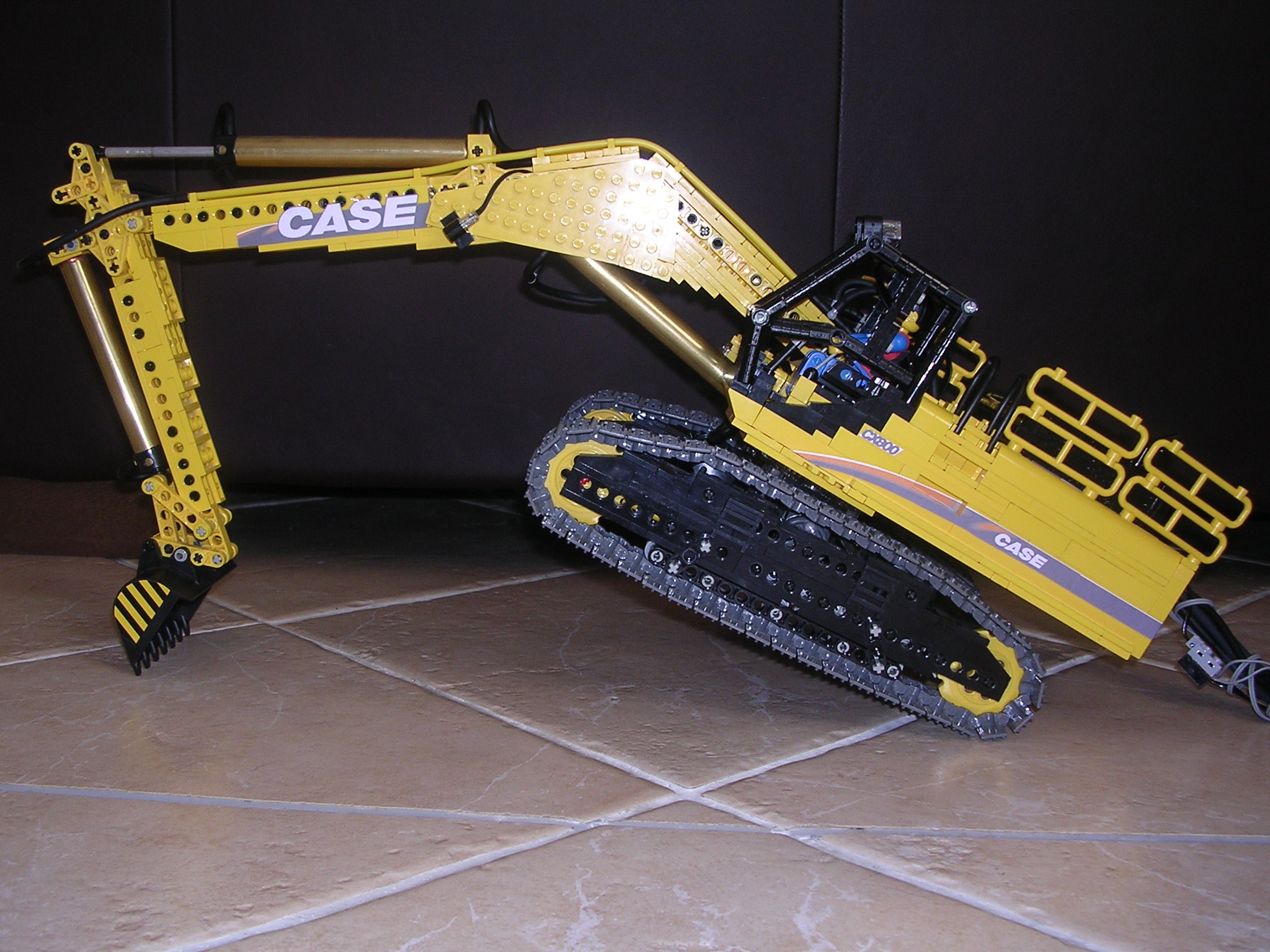

Excavator with custom pneumatics

Phitivier is a French AFOL, who also decided to build a remotely controlled LEGO TECHNIC excavator. It is an 80 ton. CASE CX800 machine.

There are some PF motors on-board to move the undercarriage and rotate the cab, while the boom, dipper and bucket are operated by pneumatic cylinders.

On the remote unit there is a PF IR remote, to control the excavator undercarriage motors, and two additional PF M-motors for a compressor that feeds the model pneumatics, via a few umbilical pneumatic tubes.

Main point of interest of this excavator, are their unique and extra long pneumatic cylinders custom made by the author.

It is a characteristic from large size excavator TECHNIC models, to require long cylinders well above those produced by LEGO. While long ago some other builders have solved the problem of not having appropriate LEGO cylinders off-the-shelf, using ropes and dummy cylinders. many others (LEGO inclusive) have used the standard ones in a back-to-back setup to double their operative length. However, achieving this way a functional but quite unrealistic solution.

This is the point where some innovative minds, decide to go for customized solutions. And so Pithivier57 did also 4.

There are some PF motors on-board to move the undercarriage and rotate the cab, while the boom, dipper and bucket are operated by pneumatic cylinders.

On the remote unit there is a PF IR remote, to control the excavator undercarriage motors, and two additional PF M-motors for a compressor that feeds the model pneumatics, via a few umbilical pneumatic tubes.

Main point of interest of this excavator, are their unique and extra long pneumatic cylinders custom made by the author.

It is a characteristic from large size excavator TECHNIC models, to require long cylinders well above those produced by LEGO. While long ago some other builders have solved the problem of not having appropriate LEGO cylinders off-the-shelf, using ropes and dummy cylinders. many others (LEGO inclusive) have used the standard ones in a back-to-back setup to double their operative length. However, achieving this way a functional but quite unrealistic solution.

This is the point where some innovative minds, decide to go for customized solutions. And so Pithivier57 did also 4.

19/07/10

EXCAVATOR CALCULATIONS

excavator will operate at maximum digging or climbing the cliffs to make it work But the minimum operating at the time he walked in the area of flat or even at standstill Meaning: rare construction tools that work for 60 minutes / hour à OPERATINGFACTOR

Sample calculation of fuel consumption Excavator:

.Work for loading trucks with soil

.Operates at max for 5 seconds to fill bucket

.Operates normal for Swing & dumping for 15 seconds

.Operates standard (average) 50 minutes / hour

1. Machine factors:

• Filling the bucket: x 1 = 0250 _5_ 20

• Swing & Dump: _15_ x 0.5 = 0375 20

• Filling the bucket: x 1 = 0250 _5_ 20

• Swing & Dump: _15_ x 0.5 = 0375 20

Total factor = 0625

2. Time factor:

50/60 = 0833

Thus, Factor Operation = 0833 x 0625 = 0520

So cons. BHN fuel = 0520 x 160 x 12:15 = 12:48 liters / hour

3. Lubricant

Replacement of lubricant

.For normal device operation à 100-200 hours

.For operation in dusty areas once every 50 hours à substituted

12/07/10

Excavator Brush Mower - for Forestry

Using the reach of the excavator makes it a powerful companion. Even mini excavators can make short work of that tall roadside bank that has become overgrown. Made to match the hydraulic flow of mini excavators, these brush mowers from Rockhound pack a serious punch. Larger full size trackhoes can harness the power of the larger forestry mulchers that we have available. These mulchers devour underbrush and small trees for cleaning up your over grown property projects.

Safely cut and mulch material quickly with these forestry that feature a Universal bolt on excavator bucket style mount, and High strength welded steel unitized structure for long lasting durability!

03/07/10

Excavator Thumb

Excavator Thumb - Fixed and Hydraulic

Go from just a digger to a GRABBER! You are going to find the right thumb configuration for you excavator. There are two different configurations to choose from, the fixed thumb that is cost effective, or the much preferred hydraulic thumb which will allow for better control and larger object moving tasks.

Go from just a digger to a GRABBER! You are going to find the right thumb configuration for you excavator. There are two different configurations to choose from, the fixed thumb that is cost effective, or the much preferred hydraulic thumb which will allow for better control and larger object moving tasks.

Rigid Thumbs are also available and are equally reliable for picking up objects and at a substantial cost savings versus it's hydraulic moving version.

Go from just a digger to a GRABBER! You are going to find the right thumb configuration for you excavator. There are two different configurations to choose from, the fixed thumb that is cost effective, or the much preferred hydraulic thumb which will allow for better control and larger object moving tasks.

Go from just a digger to a GRABBER! You are going to find the right thumb configuration for you excavator. There are two different configurations to choose from, the fixed thumb that is cost effective, or the much preferred hydraulic thumb which will allow for better control and larger object moving tasks. Rigid Thumbs are also available and are equally reliable for picking up objects and at a substantial cost savings versus it's hydraulic moving version.

01/07/10

20/06/10

Heavy equipment (construction)

From Wikipedia, the free encyclopedia

Jump to: navigation, search

Heavy equipment refers to heavy-duty vehicles, specially designed for executing construction tasks, most frequently, ones involving earthwork operations. They are also known as, construction equipment, construction plant, earth movers, engineering vehicles, or just plain equipment. They usually comprise five equipment systems: implement, traction, structure, power train, control and information. Heavy equipment functions through the mechanical advantage of a simple machine, the ratio between input force applied and force exerted is multiplied Currently most equipment use hydraulics as a primary source of transferring power. The use of heavy equipment has a long history; the ancient Roman engineer Vitruvius (1st century BCE) gave detailed descriptions of heavy equipment and cranes in ancient Rome in his treatise De architectura.Implements and Hydromechanical Work Tools

- auger

- backhoe

- bale spear

- broom

- bulldozer blade

- clam shell bucket

- cold plane

- demolition shears

- equipment bucket

- excavator bucket

- forks

- grapple

- hydraulic hammer, hoe ram

- hydraulics

- hydraulic tilting bucket (4-in-1)

- landscape tiller

- material handling arm

- mechanical pulverizer, crusher

- multi processor

- pavement removal bucket

- pile driver

- power take-off (PTO)

- quick coupler

- rake

- ripper

- rotating grab

- sheeps foot compactor

- skeleton bucket

- snow blower

- stump grinder

- stump shear

- thumb

- tiltrotator

- trencher

- vibratory plate compactor

- wheel saw

19/06/10

Facts & Figures

The forklift is a powered truck fitted with steel forks on its front end, used to lift and transport material. The two parallel steel forks slide beneath the material, often loaded onto a wooden pallet or skid, and then hoisted. Most are fitted with small wheels and are really only practical on finished or paved surfaces. Some forklifts carry their cargo on one side of the vehicle; these are called sideloaders. Though small by comparison to most heavy equipment vehicles, it has become indispensible for the warehousing and manufacturing sectors. Major manufacturers of forklifts (by market share) include Toyota, KION Group, Jungheinrich, NAACO Industries, Inc. (which includes Yale and Hyster brands), Komatsu, Manitou, Mitsubishi, Nissan, Caterpillar, Clark, and Crown Equipment, though many more brands are available among used forklifts. (Over the years, many other brands such as Allis-Chalmers have either gone out of business or been assumed into larger companies through acquisitions.)

The forklift is a powered truck fitted with steel forks on its front end, used to lift and transport material. The two parallel steel forks slide beneath the material, often loaded onto a wooden pallet or skid, and then hoisted. Most are fitted with small wheels and are really only practical on finished or paved surfaces. Some forklifts carry their cargo on one side of the vehicle; these are called sideloaders. Though small by comparison to most heavy equipment vehicles, it has become indispensible for the warehousing and manufacturing sectors. Major manufacturers of forklifts (by market share) include Toyota, KION Group, Jungheinrich, NAACO Industries, Inc. (which includes Yale and Hyster brands), Komatsu, Manitou, Mitsubishi, Nissan, Caterpillar, Clark, and Crown Equipment, though many more brands are available among used forklifts. (Over the years, many other brands such as Allis-Chalmers have either gone out of business or been assumed into larger companies through acquisitions.) Forklift operators must be well trained to operate the machine safely and effectively. Because most models steer from the rear, manouevering quickly can take some getting used to. Additionally, moving with a load held high upon the forks can upset the forklift's low center of gravity, and risk tipping. To keep the forklift balanced, some machines have a counterweight at the back, though in most cases it is the actual engine or battery that acts as the rear weight. Most forklifts have an overhead guard above the cab to protect the operator from falling debris. The exception would be those motorized pallet jacks upon which the operator stands.

18/06/10

Heavy Equipment Basic Unit Price Estimates

The price of the basic unit of heavy equipment consists of:

• Cost plan (initial cost or capital cost) ---> Owning Cost

• operation & maintenance costs (direct operational and maintenance costs) -----> Operational Cost

• Cost plan (initial cost or capital cost) ---> Owning Cost

• operation & maintenance costs (direct operational and maintenance costs) -----> Operational Cost

Would cost

Would cost (return on capital and interest) each year is calculated as follows:

Would cost (return on capital and interest) each year is calculated as follows:

Where:

G | = | cost per hour would |

B | = | price of a local tool • If the procurement of equipment not through dealers, which are referred to the local price of the CIF price plus handling cost (entrance fees, rental fees incliring warehouse, freight etc) to the buyers warehouse • When buying local means through the dealer / agent is a price to the buyer's warehouse |

C | = | The value of residual (salvage value) the value / price of the related equipment after its economic life ends. Usually this value is taken 10% of the initial cost (cost of a local appliance) |

D | = | factor installment / return on capital |

A | = | economic life of equipment (Economic Life Years) in the year depending on length of usage levels and standards of the manufacturer |

F | = | Insurance costs, taxes, etc. per year. The value is usually taken for two of the initial cost per mile or two per cent of the remaining value of equipment F = 0.002*B atau F = 0,02*C |

W | = | Number of hours of work tools in a single year • For heavy duty equipment (possible to work continuously throughout the year) is considered 8 hours / day and 250 days / year, then: W = 8 * 250 * 1 = 2000 hours / year • For equipment that is being considered on duty eight hours / days and 200 days / year, then: W = 8 * 200 * 1 = 16 000 hours / year For light duty equipment is considered 8 hours / day and 150 days / year, then: W = 8 * 150 * 1 = 1200 hours / year |

Operation and Maintenance Costs

Operating and maintenance costs are theoretically

The amount of operating and maintenance costs of each unit of equipment that is used is calculated as follows:

The cost of fuel and maintenance costs

Fuel costs (H)

Supplies of fuel per hour taken from the relevant equipment manual. Fuel requirement is a requirement of fuel for the propulsion machinery following fuel used for the production process (eg AMP include fuel for heating and drying aggregate),.

Lubricants (I)

Lubricant material which includes engine oil material, the hydraulic oil, transmission oil, power steering lubricants, grease and so forth. Needs lubricant per hour can be calculated based on the needs of oil divided by how many hours required will need to replace oil (oil type and conformed to the manual of the relevant equipment)

Cost of care / workshop (J)

Maintenance costs include the cost of replacing oil filter, filter / filters, and others.

The cost of repairs / spare parts (K)

• Cost of replacement tires

• The cost of replacing worn parts (not spare parts) such as conveyor belts, sieve for crushed stone aggregate / AMP, etc.

Reimbursement • battery / battery

• Improved tools

Operator (M)

Wages in the operating costs are usually divided between wages for operators / drivers and maid service wages. The amount of wages for operators / drivers and helpers are calculated according to the "large wage calculation" in which wages accounted for operators and assistants per hour wage an effective hours of work.

Operation and maintenance costs approach

Given the many variety of equipment from various brands that will be used, the estimator will have difficulty if the calculation of operating and maintenance costs using the manual of each instrument in question. To simplify the calculation of operating costs and maintenance of the equipment can be used in formulas that apply the approach to the whole range of equipment.

Because this formula approach to nature, so if the formula is applied to calculate the cost of operation and maintenance of one kind peraltan results will be less accurate. But if the equipment is used to calculate all the results are still within the bounds of reasonableness.

Calculation formulas approach the operation and maintenance costs are as follows:

Fuel costs (H)

The amount of fuel used for the engine is hung from the large machines used kapasitass measured by HP (horse power).

H = (05.12 s / d 17.05)% * HP

Where:

H = amount of fuel used in one hour (liters)

HP = horse power

For light duty tool multiplier is used 12.5%, while for heavy duty equipment used in the multiplier 17.5%.

Lubricant Cost (I)

The amount of lubricant (the use of lubricants including grease) used for the equipment concerned is calculated based on engine capacity, as measured by HP.

I = (1 s / d 2)% * HP

Where:

I = the amount of lubricant consumption in the first hour (liters)

HP = horse power

For the simple equipment used in the multiplier 1%, whereas for a fairly complex equipment used in the multiplier 2%.

The cost of repairs and maintenance (K)

For calculating the cost of spare parts, tires, batteries and repair equipment, etc. associated with less improvement in the per-use approach to working hours as follows:

K = (05.12 s / d 17.05)% * B / W

Where:

B = cost of equipment

W = number of working hours within one year

For light duty tool multiplier is used 12.5%, while for heavy duty equipment used in the multiplier 17.5%.

Equipment rental costs

Equipment rental fee per hour is the sum would cost + operating and maintenance costs.

Problem:

Calculate the cost of certain and maintenance costs + operating costs Excavator with 80 HP power and capacity of 0.5 m3. Other data as follows:

• The economic life : 5 years

• Working hours in a year : 2000 hours

• The price of the appliance: Rp. 2,000,000,000, -

• Interest rate : 20% per year

• Wage operators : Rp. 12 500, - per hour

• Wage assistant operator : Rp. 7500, - per hour

• diesel fuel : Rp. 4500, - per liter

• Lubricating Oil : USD. 29 000, - per liter

Operating and maintenance costs are theoretically

The amount of operating and maintenance costs of each unit of equipment that is used is calculated as follows:

The cost of fuel and maintenance costs

Fuel costs (H)

Supplies of fuel per hour taken from the relevant equipment manual. Fuel requirement is a requirement of fuel for the propulsion machinery following fuel used for the production process (eg AMP include fuel for heating and drying aggregate),.

Lubricants (I)

Lubricant material which includes engine oil material, the hydraulic oil, transmission oil, power steering lubricants, grease and so forth. Needs lubricant per hour can be calculated based on the needs of oil divided by how many hours required will need to replace oil (oil type and conformed to the manual of the relevant equipment)

Cost of care / workshop (J)

Maintenance costs include the cost of replacing oil filter, filter / filters, and others.

The cost of repairs / spare parts (K)

• Cost of replacement tires

• The cost of replacing worn parts (not spare parts) such as conveyor belts, sieve for crushed stone aggregate / AMP, etc.

Reimbursement • battery / battery

• Improved tools

Operator (M)

Wages in the operating costs are usually divided between wages for operators / drivers and maid service wages. The amount of wages for operators / drivers and helpers are calculated according to the "large wage calculation" in which wages accounted for operators and assistants per hour wage an effective hours of work.

Operation and maintenance costs approach

Given the many variety of equipment from various brands that will be used, the estimator will have difficulty if the calculation of operating and maintenance costs using the manual of each instrument in question. To simplify the calculation of operating costs and maintenance of the equipment can be used in formulas that apply the approach to the whole range of equipment.

Because this formula approach to nature, so if the formula is applied to calculate the cost of operation and maintenance of one kind peraltan results will be less accurate. But if the equipment is used to calculate all the results are still within the bounds of reasonableness.

Calculation formulas approach the operation and maintenance costs are as follows:

Fuel costs (H)

The amount of fuel used for the engine is hung from the large machines used kapasitass measured by HP (horse power).

H = (05.12 s / d 17.05)% * HP

Where:

H = amount of fuel used in one hour (liters)

HP = horse power

For light duty tool multiplier is used 12.5%, while for heavy duty equipment used in the multiplier 17.5%.

Lubricant Cost (I)

The amount of lubricant (the use of lubricants including grease) used for the equipment concerned is calculated based on engine capacity, as measured by HP.

I = (1 s / d 2)% * HP

Where:

I = the amount of lubricant consumption in the first hour (liters)

HP = horse power

For the simple equipment used in the multiplier 1%, whereas for a fairly complex equipment used in the multiplier 2%.

The cost of repairs and maintenance (K)

For calculating the cost of spare parts, tires, batteries and repair equipment, etc. associated with less improvement in the per-use approach to working hours as follows:

K = (05.12 s / d 17.05)% * B / W

Where:

B = cost of equipment

W = number of working hours within one year

For light duty tool multiplier is used 12.5%, while for heavy duty equipment used in the multiplier 17.5%.

Equipment rental costs

Equipment rental fee per hour is the sum would cost + operating and maintenance costs.

Problem:

Calculate the cost of certain and maintenance costs + operating costs Excavator with 80 HP power and capacity of 0.5 m3. Other data as follows:

• The economic life : 5 years

• Working hours in a year : 2000 hours

• The price of the appliance: Rp. 2,000,000,000, -

• Interest rate : 20% per year

• Wage operators : Rp. 12 500, - per hour

• Wage assistant operator : Rp. 7500, - per hour

• diesel fuel : Rp. 4500, - per liter

• Lubricating Oil : USD. 29 000, - per liter

14/06/10

Various kinds of heavy equipment

1. Front Shovel

Function: This heavy equipment used to excavate soil and rock.

2. Motor Grader

|

Function: can be used to flatten the ground and form a ground surface. Motor graders can also be used for mixing the soil and spread a mixture of soil and asphalt. In general, motor graders are used in projects and maintenance of roads and with the ability to brgerak, motor graders are often used in projects airfield.

3. Dragline

Function: used to excavate soil and rock.

4. Truck Mixer

Function: To stirring mixture of concrete and has the advantage because it can deliver concrete results to the location diiingkan stirring. This tool is also used as an agitator truck carrying the mortar from the mixing plant to the project.

5. Crawel Crane

Function: as a means of transportation that can move 360 º in the project site while doing a job.

6. Scraper

Function: heavy equipment that serves to dredge, transport, and sow the dredging of a layered soil. Scaper can also be used as a means of transportation for a relatively long distance (± 2000 m) on flat ground with a tire-wheel drive equipment.

7. Truck crane

Function: a transporter normally used in construction projects. By way of lifting materials to be moved, move horizontally, then lowered in place of the desired material.

04/06/10

Heavy equipment for construction

Heavy equipment for construction

(a) Dragline. Singapore and Malaysia generally use dragline. The operations consist of bringing to site a track-mounted crane. With the crane are many 0.1 × 0.3 × 4.0 to 5.0 m planks which are self-laid by the crane for its own base. As work progresses, the planks are self-shifted by the crane so that it is resting at all times on a series of platform planks preventing it from bogging down in mud.

This particular equipment is particularly good for dike construction, canal digging and deepening (Fig. 6.9). Hence, it is suited for excavating shrimp trapping ponds in order to have deeper water. However, it is not practical for large-scale within-compartment-levelling because of its being too slow and unwieldy. Its use is also limited where mass hauling of earth in some areas for dike building is involved. It is by design, an equipment for in-place working. There is now in the market a crane mounted on LGP (low ground pressure) tracks. This makes the crane more maneuverable in swampy areas and cuts its non-productive plank-transferring time by half. This crane can be equipped with clam shell buckets.

Fig. 6.9 Range diagram and limits of work of drag line as defined for the construction of the perimeter dike

(After Hechanava and Tiensongrusmee, 1980)

(b) Dozer-crawlers (Fig. 6.10). This particular equipment is good for levelling provided the load-bearing capacity of the soil can support the equipment weight. Recent designs of these equipment are provided with mechanisms which improves speed and maneuverability, thus cutting down construction time. The effective working range of most dozers in dry soil conditions vary from 20 to 40 m.

Most crawler manufacturers have now incorporated LGP tracks to their line of crawlers to enable it to work on wet soils. On LGP, the ground pressure usually is around 0.28 kg/cm2. The LGP crawlers come in a variety of sizes, ranging from 20 to 200 BHp. One has therefore a good choice to suit the area to be developed or the transport situation to the work area. In some instances, small LGP dozers are chosen over a large one for convenience in transporting the equipment to the job site by raft or passing on bridges which have limited load capacity.

(c) Hydraulic excavators, backhoe, shovels, cranes, pay loaders (Fig. 6.10). These are equipment that can also be used to advantage in fishpond projects. One advantage the hydraulic equipment have over cable cranes are their fast action and flexibility to adapt to a variety of situations. These can also be adapted with clam shells and grapplers and can be used for uprooting small tree stumps.

(d) Scrapers, dump trucks, wheel-type loaders (Fig. 6.10). These may also be used effectively where soil conditions permit.

(e) Suggestions on mechanization. Much waste has been observed in the use of mechanized equipment. In order to be able to adopt this method with success, one must know the following: (i) capacity; (ii) limitations; (iii) limit of maximum operating range; (iv) ground pressure; (v) working conditions; (vi) amount of work to be done; (vii) type of work required; and (viii) cost per unit of work accomplished.

There are equipment now especially fabricated for reclamation and swamp work. These types can be used in mangroves effectively. However, one should be conversant with the different types of equipment and be able to judge critically the type of equipment needed after seeing the project area. There are some large equipment which can be taken apart into several components and reassembled at job-site. Some cranes and hydraulic lifters are also designed to be barge-mounted with their tracks on while on the shore.

In addition, the economical or effective range of the equipment should also be known. At what distance should one consider a loader and a dump truck combination over a crawler? It would be uneconomical beyond about 35 m due to its track wear and long cycle time. Beyond 35 m on volume of soil movement, one might want to employ combination pay loaders with several dump trucks. The economics of this operation should be worked out. Scrapers (self-loading and crawler-assisted) are ideal for large projects. Dredges can be used effectively too. Under special situations, jetting pumps can effectively facilitate uprooting of stumps. All of the above require a thorough knowledge of the project site peculiarities as well as the different equipment available, their specifications, capacities and limitations. An expert's advise in this field is usually necessary.

(a) Dragline. Singapore and Malaysia generally use dragline. The operations consist of bringing to site a track-mounted crane. With the crane are many 0.1 × 0.3 × 4.0 to 5.0 m planks which are self-laid by the crane for its own base. As work progresses, the planks are self-shifted by the crane so that it is resting at all times on a series of platform planks preventing it from bogging down in mud.

This particular equipment is particularly good for dike construction, canal digging and deepening (Fig. 6.9). Hence, it is suited for excavating shrimp trapping ponds in order to have deeper water. However, it is not practical for large-scale within-compartment-levelling because of its being too slow and unwieldy. Its use is also limited where mass hauling of earth in some areas for dike building is involved. It is by design, an equipment for in-place working. There is now in the market a crane mounted on LGP (low ground pressure) tracks. This makes the crane more maneuverable in swampy areas and cuts its non-productive plank-transferring time by half. This crane can be equipped with clam shell buckets.

Fig. 6.9 Range diagram and limits of work of drag line as defined for the construction of the perimeter dike

(After Hechanava and Tiensongrusmee, 1980)

|

| The cost of using draglines vary with the kind of soil material and its size. The effective working range depends on the length of boom |

(b) Dozer-crawlers (Fig. 6.10). This particular equipment is good for levelling provided the load-bearing capacity of the soil can support the equipment weight. Recent designs of these equipment are provided with mechanisms which improves speed and maneuverability, thus cutting down construction time. The effective working range of most dozers in dry soil conditions vary from 20 to 40 m.

|

Fig. 6.10 Some heavy equipment for fish farm construction (After Tarnchalanukit, 1982) |

Most crawler manufacturers have now incorporated LGP tracks to their line of crawlers to enable it to work on wet soils. On LGP, the ground pressure usually is around 0.28 kg/cm2. The LGP crawlers come in a variety of sizes, ranging from 20 to 200 BHp. One has therefore a good choice to suit the area to be developed or the transport situation to the work area. In some instances, small LGP dozers are chosen over a large one for convenience in transporting the equipment to the job site by raft or passing on bridges which have limited load capacity.

(c) Hydraulic excavators, backhoe, shovels, cranes, pay loaders (Fig. 6.10). These are equipment that can also be used to advantage in fishpond projects. One advantage the hydraulic equipment have over cable cranes are their fast action and flexibility to adapt to a variety of situations. These can also be adapted with clam shells and grapplers and can be used for uprooting small tree stumps.

(d) Scrapers, dump trucks, wheel-type loaders (Fig. 6.10). These may also be used effectively where soil conditions permit.

(e) Suggestions on mechanization. Much waste has been observed in the use of mechanized equipment. In order to be able to adopt this method with success, one must know the following: (i) capacity; (ii) limitations; (iii) limit of maximum operating range; (iv) ground pressure; (v) working conditions; (vi) amount of work to be done; (vii) type of work required; and (viii) cost per unit of work accomplished.

There are equipment now especially fabricated for reclamation and swamp work. These types can be used in mangroves effectively. However, one should be conversant with the different types of equipment and be able to judge critically the type of equipment needed after seeing the project area. There are some large equipment which can be taken apart into several components and reassembled at job-site. Some cranes and hydraulic lifters are also designed to be barge-mounted with their tracks on while on the shore.

In addition, the economical or effective range of the equipment should also be known. At what distance should one consider a loader and a dump truck combination over a crawler? It would be uneconomical beyond about 35 m due to its track wear and long cycle time. Beyond 35 m on volume of soil movement, one might want to employ combination pay loaders with several dump trucks. The economics of this operation should be worked out. Scrapers (self-loading and crawler-assisted) are ideal for large projects. Dredges can be used effectively too. Under special situations, jetting pumps can effectively facilitate uprooting of stumps. All of the above require a thorough knowledge of the project site peculiarities as well as the different equipment available, their specifications, capacities and limitations. An expert's advise in this field is usually necessary.

Langganan:

Postingan (Atom)